Highly technological projects

The company’s heritage is made up by human resource and productive means that utilized to their best capacity allow us to give flexible and quick responses even to the most demanding markets.

The production types, in which we have many years of experience, are realized by precision machining, obtained by turning, milling, and correction.

The processes can be summed up as follows:

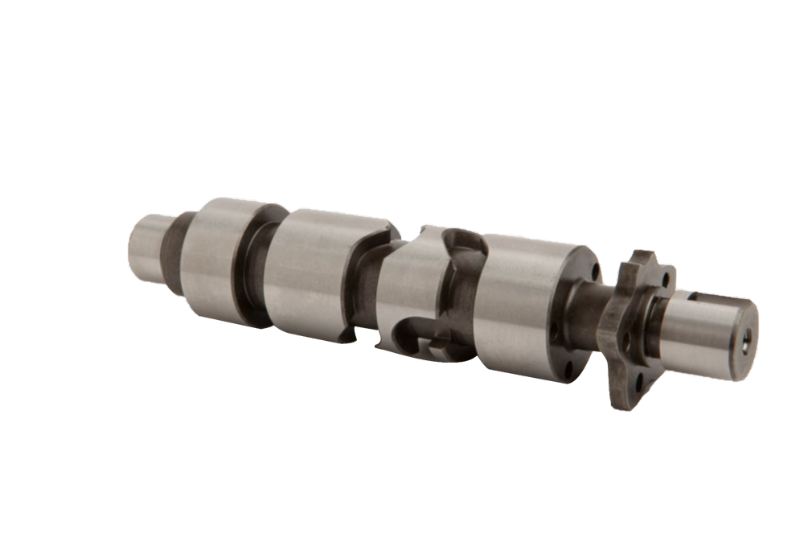

Shafts: turning of shafts, axes, semi-worked or finished coned pinions, obtained by prints or from bars, in supply or tolling, with execution of pre correction thermal treatments and superficial treatments when requested.

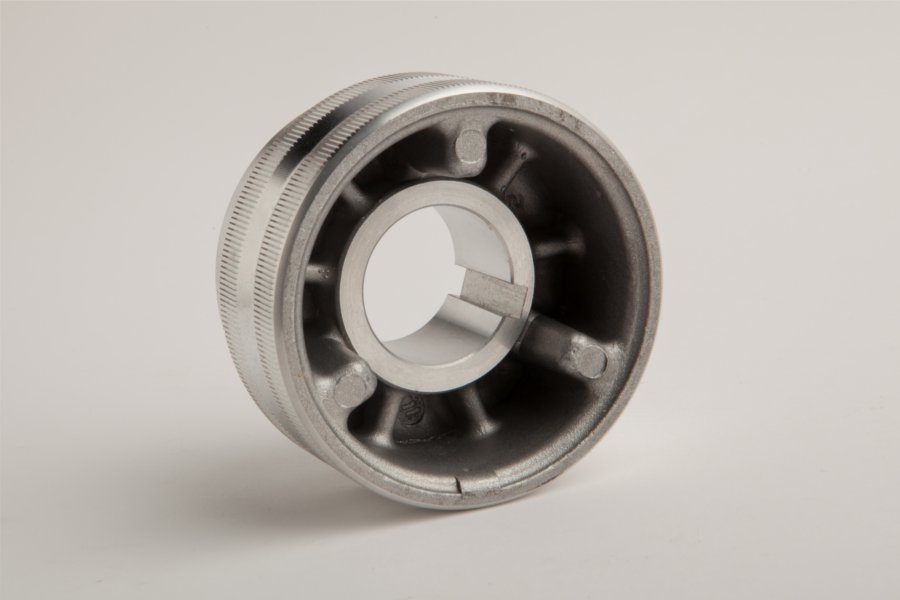

Finished parts: pieces obtained from bars or prints, with the execution of pre correction thermal treatments and superficial treatments such as galvanizing, browning, dacromet, phosphorylation, nickel, and polish. We are equipped to assemble the product with store bought components or components provided by the customers, in order to deliver a product ready for mounting.

Prints: turning and milling of prints, even with irregular geometric designs, in supply or tolling, with subsequent processes and possible superficial treatments at work completed.

Series and pre-series: the types of machines we use allow to produce large projects, but also to realize special samples of small units. This allows us to participate with the customer in the engineering of the product, from the prototype to the series.

This allows us to support the customer in product engineering, from prototypes to series.